As a company, we value craftsmanship and innovation. We’re always looking to create improved methods of bringing your ring ideas to life. The opaque jewellery making industry and its manufacturing processes haven’t changed for hundreds of years. It is only recently that the process been disrupted with the introduction of 3D printing, altering the traditional way of making jewellery, allowing for a plethora of possibilities and creativity.

At Taylor & Hart, we have embraced this method as we believe it ensures jewellery of excellent quality, without losing the integrity and emotion of a piece. In this article, we explore the journey of a bespoke engagement ring and look at how 3D printing elevates the process, allowing our customers, designers and craftsmen to focus on what is truly important.

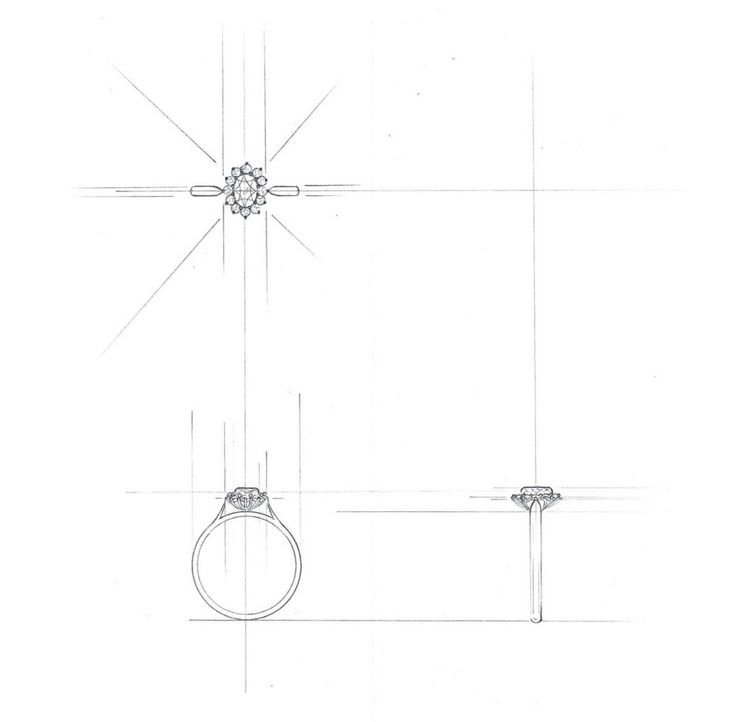

Stage 1: The initial design brief and sketch

To begin the process, each customer is connected with one of our design consultants through our website, where they can share their ideas and discuss their requirements. The design consultant will share their designs, sometimes even sketching some options, ready to be passed to the CAD (computer aided design) designer. The CAD designer then creates a 3D render of the ring design for the customer to review.