What is an ethical engagement ring?

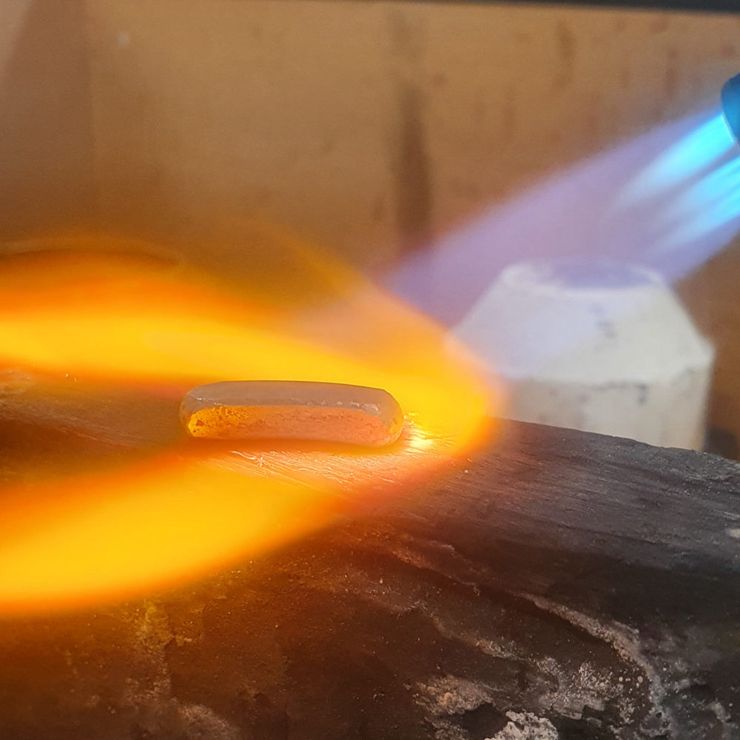

Your ring is the embodiment of something magical. Handcrafted from diamonds, gemstones, and precious metals, it represents the loving bond you’ve built with your partner. As jewelers, we believe that using sustainable materials makes a ring all the more meaningful, not just for us but for the person who wears and loves it everyday.

This is what we mean by an “ethically sourced” ring. It’s a piece of jewelry that’s been crafted with materials specially chosen for their provenance and origin, qualities that are determined against a set of ethical standards. It means that the gemstones and metals used in your ring come from conflict-free economies, have had a minimal impact on the environment, and have been mined or created by people benefiting from fair and safe working conditions.